The fight against climate change has taken a significant leap forward thanks to an innovative partnership between satellite technology, on-the-ground expertise, and the commitment of local operators. This groundbreaking collaboration has demonstrated the power of swift action and advanced technology in detecting and repairing methane leaks, a major contributor to greenhouse gas emissions. The results? Substantial reductions in methane emissions, achieved within a matter of hours.

But how did this remarkable feat come to be? It all began with the combined efforts of GHGSat, Carbon Limits, TP Europe, and a dedicated local operator. Each brought their unique expertise to the table, forming a formidable team in the battle against methane emissions.

Satellite Observations in Identifying Methane Plumes

In the quest to mitigate methane emissions, the first step is always detection. And that’s where satellite technology comes in. Imagine having an eye in the sky, constantly scanning the Earth’s surface for signs of methane plumes. That’s precisely what GHGSat’s satellites do, providing a bird’s-eye view of methane emissions that might otherwise go unnoticed.

But satellite detection is just the beginning. Once a methane plume is identified, the real work begins on the ground. That’s where the expertise of Carbon Limits and TP Europe comes into play.

GHGSat’s Crucial Role in Detecting Methane Emissions

GHGSat, a pioneering company in the field of satellite-based greenhouse gas monitoring, has been instrumental in detecting methane plumes across the globe. Their advanced satellites are equipped with high-resolution sensors capable of identifying methane emissions with unparalleled accuracy. This technology has revolutionized the way we monitor and address methane leaks, providing a level of visibility that was once impossible.

But how does GHGSat’s technology work? In simple terms, their satellites use a technique called “spectroscopy” to analyze the unique fingerprint of methane in the atmosphere. By measuring the absorption of sunlight by methane molecules, GHGSat’s satellites can pinpoint the location and magnitude of methane leaks with incredible precision.

Carbon Limits’ Coordination of LDAR Campaigns

While GHGSat’s satellites provide the bird’s-eye view, Carbon Limits brings its expertise in coordinating Leak Detection and Repair (LDAR) campaigns on the ground. LDAR is a systematic approach to identifying and fixing methane leaks in industrial facilities, and it’s a crucial component of any effective methane reduction strategy.

Carbon Limits works closely with local operators to plan and execute LDAR campaigns, ensuring that every potential leak source is thoroughly inspected. Their team of experts uses advanced tools and techniques to locate and quantify methane leaks, providing valuable data that helps operators prioritize repairs and minimize emissions.

But what exactly does an LDAR campaign entail? Here’s a quick overview:

- Planning: Carbon Limits works with the operator to identify potential leak sources and develop a comprehensive inspection plan.

- Inspection: Using advanced tools like optical gas imaging cameras and portable analyzers, the LDAR team systematically inspects each potential leak source.

- Quantification: When a leak is detected, the team measures its size and flow rate to determine its environmental impact.

- Repair: The operator’s maintenance team is dispatched to repair the leak as quickly as possible.

- Verification: After the repair is complete, the LDAR team verifies that the leak has been successfully fixed.

By coordinating these LDAR campaigns, Carbon Limits helps operators stay on top of their methane emissions and ensures that leaks are identified and repaired in a timely manner.

TP Europe’s Expertise and Technology

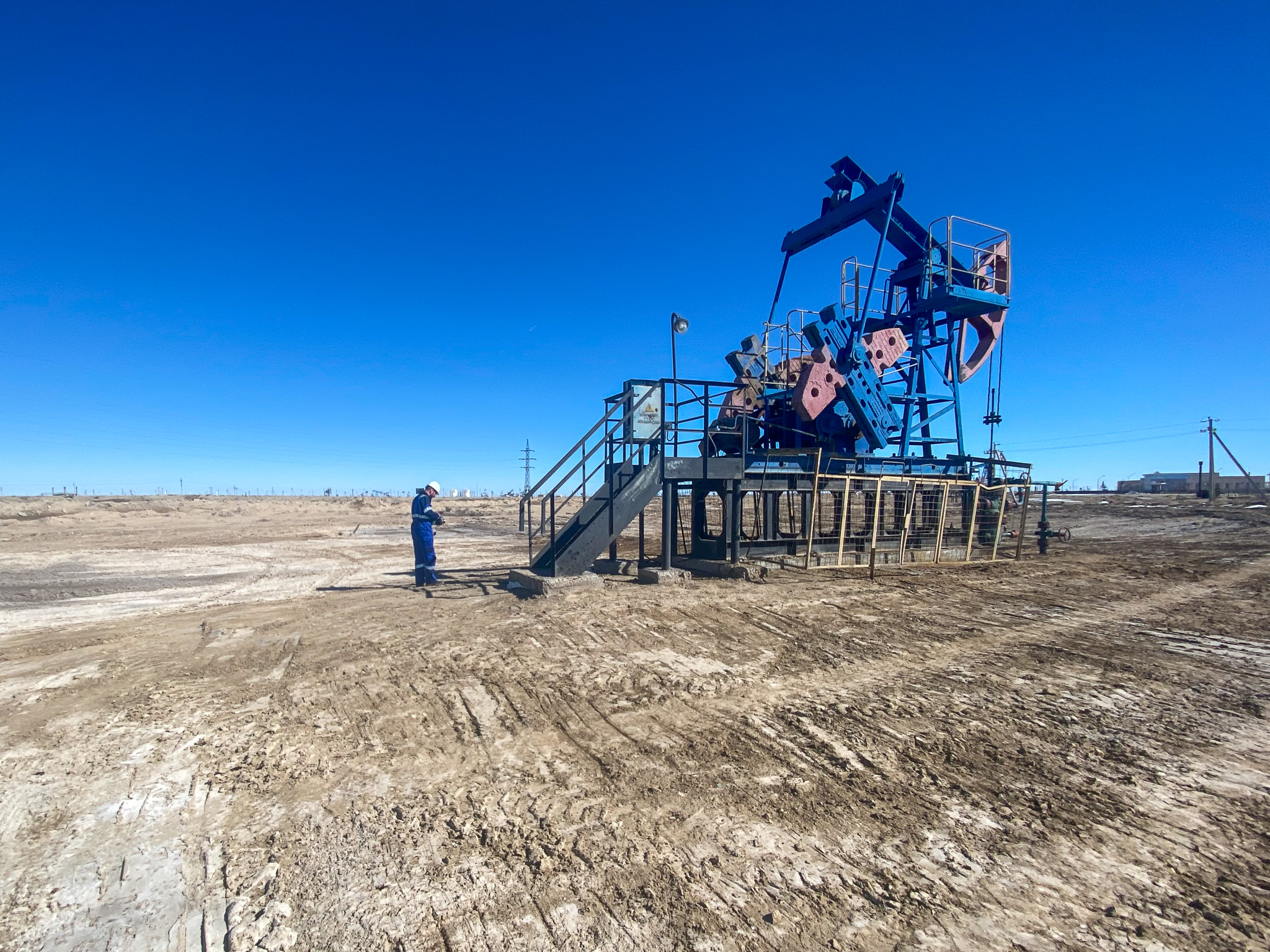

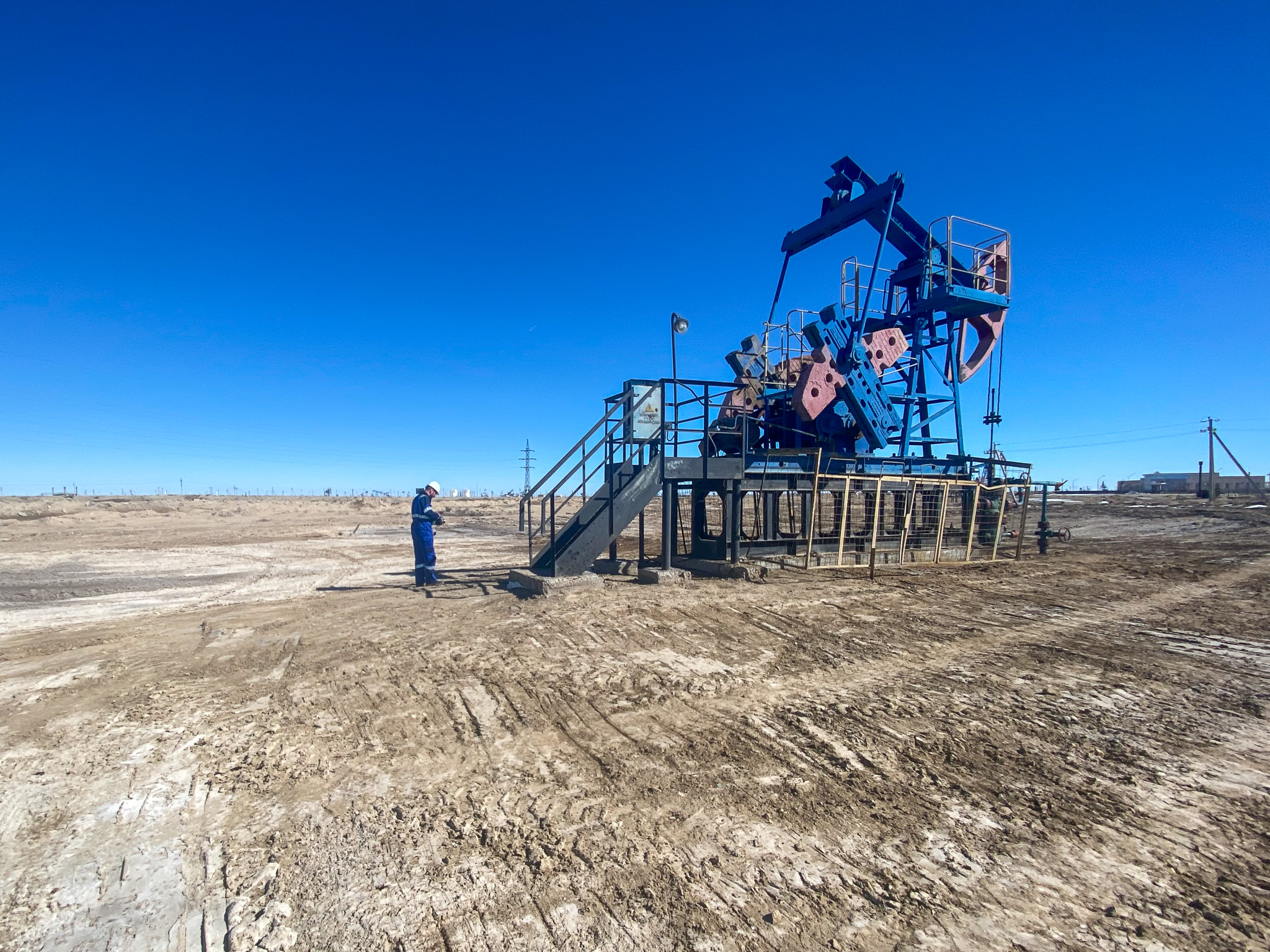

Once a methane plume has been detected by GHGSat’s satellites, the next step is to pinpoint the exact location of the leak on the ground. That’s where TP Europe comes in. With their state-of-the-art infrared camera technology and extensive experience in methane leak detection, TP Europe’s team can quickly and accurately identify the source of the leak.

But how does an infrared camera help locate methane leaks? It all comes down to the unique properties of methane gas. Methane absorbs infrared light in a specific wavelength range, which means that it shows up as a bright spot on an infrared camera’s display. By using this technology, TP Europe’s team can see methane leaks that are invisible to the naked eye.

Infrared Camera Technology: Pinpointing Leak Locations

Imagine trying to find a needle in a haystack. Now imagine that the needle is invisible. That’s the challenge of locating methane leaks in a vast industrial facility. But with infrared camera technology, that invisible needle suddenly becomes a bright, glowing beacon.

TP Europe’s infrared cameras are specifically designed to detect methane leaks. They use a specialized filter that allows only the infrared wavelengths absorbed by methane to pass through, creating a high-contrast image that clearly shows the location of the leak. This technology is so sensitive that it can detect leaks as small as 0.1 grams per hour, which is about the weight of a single grain of rice.

But infrared cameras are just one tool in TP Europe’s leak detection arsenal. They also use portable analyzers and other advanced equipment to quantify the size and flow rate of each leak, providing valuable data that helps prioritize repairs and estimate the environmental impact of the leak.

TP Europe’s Experience in Methane Leak Detection

Of course, technology is only as effective as the people who use it. That’s where TP Europe’s extensive experience in methane leak detection comes into play. Their team of experts has years of hands-on experience in locating and quantifying methane leaks in a wide range of industrial settings.

But what sets TP Europe apart from other leak detection companies? It’s their commitment to staying at the forefront of technology and best practices. They invest heavily in training and equipment to ensure that their team has the skills and tools they need to get the job done right. TP Europe’s experience also allows them to work efficiently and effectively in the field. They know how to navigate complex industrial facilities, identify potential leak sources, and work collaboratively with operators to minimize disruption and ensure a smooth leak detection and repair process.

In the case of the methane plume detected by GHGSat, TP Europe’s team was able to quickly mobilize to the site and begin the leak detection process. Using their infrared cameras and other advanced tools, they systematically inspected the facility and located the source of the leak within a matter of hours. This rapid response was critical in minimizing the environmental impact of the leak and preventing further emissions.

Operator’s Commitment to Swift Leak Repair

But detecting a methane leak is only half the battle. The real challenge lies in repairing the leak as quickly as possible to minimize its environmental impact. And that’s where the commitment of the local operator comes into play.

In the case of the methane plume detected by GHGSat, the local operator demonstrated an exemplary level of commitment to swift leak repair. Within minutes of being notified of the leak’s location, the operator had dispatched their maintenance team to the site, armed with the tools and expertise needed to fix the problem.

Rapid Response and Maintenance Team Deployment

Picture this: you’re in the middle of a busy workday when suddenly, an alarm sounds. There’s a methane leak in your facility, and every minute counts. What do you do?

If you’re the local operator in this case study, you spring into action. You know that a rapid response is critical in minimizing the environmental impact of the leak. That’s why you have a dedicated maintenance team on standby, ready to be deployed at a moment’s notice. But how do you ensure that your team is prepared for any situation? It all comes down to training and equipment. The local operator invests heavily in both, ensuring that their maintenance team has the skills and tools they need to tackle any leak, no matter how challenging.

In the case of the methane plume detected by GHGSat, the operator’s rapid response was a testament to their commitment to environmental stewardship. By deploying their maintenance team within minutes of being notified of the leak, they were able to minimize its duration and prevent countless tons of methane from being released into the atmosphere.

Addressing the Root Cause of Methane Leaks

But fixing the immediate problem is only part of the solution. To truly prevent future methane leaks, it’s essential to address their root cause. And that’s exactly what the local operator did in this case.

Once the leak had been repaired, the operator’s team conducted a thorough investigation to determine what had caused it in the first place. Was it a faulty valve? A corroded pipe? A design flaw in the system?

By identifying the root cause of the leak, the operator was able to take proactive steps to prevent similar incidents from occurring in the future. This might involve:

- Replacing aging equipment

- Upgrading to more leak-resistant materials

- Implementing new maintenance protocols

- Providing additional training for staff

Addressing the root cause of methane leaks is a critical step in reducing their frequency and impact over time. It’s not enough to simply fix the immediate problem; operators must be willing to invest in long-term solutions that prioritize environmental sustainability.

The Environmental Impact of Rapid Methane Leak Detection and Repair

But why does all of this matter? Why is it so important to detect and repair methane leaks as quickly as possible? The answer lies in the devastating environmental impact of methane emissions.

Methane is a potent greenhouse gas, with a global warming potential 84 times greater than carbon dioxide over a 20-year period. That means that even small methane leaks can have a significant impact on the Earth’s climate, contributing to rising temperatures, more frequent natural disasters, and other devastating consequences.

Preventing Substantial Methane Emissions

The methane plume detected by GHGSat in this case study was no small leak. In fact, it was emitting a staggering 150 kilograms of methane per hour. To put that into perspective, that’s equivalent to the methane emissions from approximately:

| Source |

Equivalent Emissions |

| Cows |

7,500 |

| Landfills |

1.5 |

| Natural gas-powered homes |

1,500 |

If left unchecked, this single leak could have released over 1.3 million kilograms of methane into the atmosphere in a single year. That’s a truly mind-boggling amount, with far-reaching consequences for our planet.

But thanks to the rapid detection and repair efforts of GHGSat, Carbon Limits, TP Europe, and the local operator, this leak was stopped in its tracks. By working together to identify and fix the problem within hours of its detection, these organizations prevented the release of a substantial amount of methane into the atmosphere.

Comparing Emissions to Large-Scale Waste Incineration Plants

To further illustrate the scale of the methane emissions prevented by this rapid leak detection and repair effort, let’s compare it to another significant source of greenhouse gas emissions: waste incineration plants. According to the local operator, the amount of methane emissions prevented by fixing this single leak is comparable to the annual emissions of the largest waste incineration plant in their home country of Norway. That’s a staggering comparison, highlighting the immense environmental impact of even a single methane leak.

But it’s not just about the numbers. It’s about the tangible impact on our planet and our communities. By preventing these methane emissions, the organizations involved in this effort have taken a meaningful step towards mitigating climate change and protecting our environment for future generations.

And that’s something we can all be grateful for. Because when it comes to fighting climate change, every action counts. Every leak detected and repaired, every ton of methane emissions prevented, brings us one step closer to a more sustainable future.

So let’s take a moment to appreciate the hard work and dedication of the teams at GHGSat, Carbon Limits, TP Europe, and the local operator. Their commitment to rapid methane leak detection and repair is a shining example of what’s possible when we work together towards a common goal.

And who knows? Maybe their success story will inspire others to follow in their footsteps, leading to even more meaningful reductions in methane emissions around the world.

Continued Success in Methane Emissions Reduction

The success story of this rapid methane leak detection and repair effort is just the beginning. The organizations involved are committed to building on this momentum and achieving even greater reductions in methane emissions over time.

But how do they plan to do it? By focusing on two key areas: identifying and mitigating super emitters, and continuing their ongoing LDAR efforts.

Identifying and Mitigating Super Emitters

Super emitters are the big kahunas of methane leaks. These are the leaks that emit a disproportionately large amount of methane compared to other sources. In fact, studies have shown that just a small percentage of leaks can account for the majority of methane emissions from a given facility or region. That’s why identifying and mitigating super emitters is such a critical priority for the organizations involved in this effort. By targeting these high-impact leaks, they can achieve significant reductions in methane emissions with relatively little effort.

But how do they find these super emitters? That’s where advanced technologies like GHGSat’s satellites and TP Europe’s infrared cameras come in. These tools allow the team to quickly scan large areas and pinpoint the biggest methane leaks, so they can be repaired as soon as possible.

In the case study we’ve been discussing, the leak detected by GHGSat was a prime example of a super emitter. By identifying and repairing this leak within hours, the team prevented a truly staggering amount of methane from being released into the atmosphere.

The Importance of Ongoing LDAR Efforts

But it’s not just about finding and fixing the big leaks. To truly minimize methane emissions over time, it’s essential to have a comprehensive and ongoing LDAR program in place.

Think of it like maintaining your car. You wouldn’t just wait until something breaks down completely before getting it fixed, right? You take it in for regular tune-ups and oil changes to keep it running smoothly and prevent bigger problems down the line. The same principle applies to methane leak detection and repair. By regularly inspecting facilities and equipment for leaks, operators can catch and fix small problems before they turn into big ones.

That’s where organizations like Carbon Limits come in. By coordinating ongoing LDAR campaigns and working closely with local operators, they help ensure that methane leaks are detected and repaired on a regular basis.

And the results speak for themselves. The team’s ongoing LDAR efforts have led to significant reductions in methane emissions from the facilities they’ve worked with. It’s a testament to the power of a proactive, long-term approach to methane mitigation.

Key Factors in Successful Methane Emissions Mitigation

So what does it take to achieve success in methane emissions mitigation? Based on the experience of the organizations involved in this effort, there are a few key factors that stand out.

Proper Tools and Knowledge

First and foremost, having the right tools and knowledge is essential. Methane leaks can be notoriously difficult to detect and quantify, especially without specialized equipment. That’s why organizations like GHGSat and TP Europe invest so heavily in advanced technologies like satellites and infrared cameras. These tools allow them to quickly and accurately identify methane leaks that might otherwise go unnoticed.

But it’s not just about having the right equipment. It’s also about having the expertise to use it effectively. The team members involved in this effort have years of experience in methane leak detection and quantification, which allows them to interpret data and make informed decisions about where to focus their efforts.

Investing in the proper tools and knowledge is a critical first step in any successful methane emissions mitigation effort.

Effective Communication and Collaboration

Another key factor in the success of this effort was the effective communication and collaboration between all of the organizations involved. Imagine trying to coordinate a complex leak detection and repair effort across multiple teams and locations. It’s like herding cats, right? But with clear communication and a willingness to work together towards a common goal, even the most challenging projects can be accomplished.

In this case study, each organization brought its own unique expertise and perspective to the table. GHGSat provided the high-level satellite data, Carbon Limits coordinated the on-the-ground LDAR efforts, TP Europe brought its advanced leak detection technology, and the local operator provided the resources and manpower to quickly repair the leak.

By working together seamlessly and communicating regularly throughout the process, these organizations were able to achieve a level of success that would have been impossible working alone.

Commitment of Local Operators

Finally, none of this would have been possible without the commitment and dedication of the local operator. Repairing a methane leak is no small task, especially when it requires shutting down equipment or disrupting normal operations. It takes a real commitment to environmental stewardship to prioritize leak repairs over short-term business concerns.

But that’s exactly what the local operator did in this case study. They recognized the importance of swift action in mitigating the environmental impact of the leak, and they didn’t hesitate to deploy their maintenance team and resources to get the job done. This level of commitment is critical to the success of any methane emissions mitigation effort. Without buy-in from local operators, even the most advanced leak detection technology and expertise can only go so far.

| Factor |

Description |

| Proper Tools and Knowledge |

Advanced technologies and expertise to quickly and accurately identify methane leaks |

| Effective Communication and Collaboration |

Clear communication and seamless coordination between all organizations involved |

| Commitment of Local Operators |

Buy-in and dedication from local operators to prioritize leak repairs over short-term business concerns |

Gratitude for Strong Partnerships and Dedicated Teams

At the end of the day, the success of this methane leak detection and repair effort comes down to the hard work and dedication of all the individuals and organizations involved.

The Value of Collaboration in Methane Emissions Reduction

Collaboration is key in the fight against methane emissions. No single organization has all the answers or resources needed to tackle this complex challenge alone.

That’s why partnerships like the one between GHGSat, Carbon Limits, TP Europe, and the local operator are so valuable. By bringing together a diverse range of expertise and perspectives, these organizations were able to achieve a level of success that would have been impossible working in isolation.

It’s a powerful reminder of the importance of collaboration in addressing global environmental challenges. By working together towards a common goal, we can achieve things that might seem impossible on our own.

Recognizing the Operator’s Competent and Dedicated Team

While the advanced technologies and expertise of organizations like GHGSat and TP Europe were certainly critical to the success of this effort, it’s important to recognize the hard work and dedication of the local operator’s team as well. These are the folks who are on the ground every day, working tirelessly to keep their facilities running safely and efficiently. They’re the ones who have to drop everything and spring into action when a leak is detected, often working long hours in challenging conditions to get the job done.

In this case study, the local operator’s maintenance team demonstrated an exceptional level of competence and dedication in repairing the methane leak. Their quick action and expertise were essential in minimizing the environmental impact of the leak. It’s a reminder that, while advanced technologies and data are certainly important, it’s the people behind them that truly make the difference. Without the hard work and dedication of teams like this one, even the most sophisticated leak detection efforts would be for naught.

So let’s take a moment to recognize and appreciate the incredible work of the local operator’s team, and all the other unsung heroes who work tirelessly every day to keep our planet clean and safe.

And let’s continue to support and encourage collaborations like this one, which bring together the best and brightest minds to tackle the global challenge of methane emissions. Because together, there’s no limit to what we can achieve.