Thermography

Introduction to TP Europe’s Thermographic Services

For decades, industries worldwide have sought solutions to enhance their energy efficiency and cost-effectiveness. TP Europe stands at the forefront of this pursuit with its top-tier thermographic services. As industries evolve, so do their needs, and TP Europe has consistently aligned its services to provide unparalleled support.

Pioneering Heat Loss Detection in Industries

- Precision Equipment: TP Europe deploys high-resolution infrared cameras capable of detecting minute temperature differences. The use of such technical equipment ensures that no anomaly, no matter how minor, escapes our detection.

- Expertise on Ground: The strength of our thermography services doesn’t just lie in our advanced equipment but also in the hands that wield them. Our trained technicians, with their in-depth knowledge of infrared technology, guarantee comprehensive inspections.

- Data-Driven Insights: Post-inspection, our experts provide detailed thermographic reports. These documents are rich in technical terms, ensuring industries get an in-depth understanding of the areas of concern.

| Parameters | Details |

|---|---|

| Equipment | High-resolution infrared cameras |

| Technicians | Highly-trained and experienced |

| Report | Detailed with technical terminologies |

Benefits of Opting for Thermographic Inspections

The utilization of thermographic inspections, especially in industrial settings, has revolutionized the way businesses approach energy efficiency and maintenance. Beyond merely visualizing heat patterns, these inspections have a plethora of benefits that encompass financial, environmental, operational, and regulatory dimensions.

Financial Advantages: More Than Just Cost Savings

- Operational Longevity: By identifying and addressing energy inefficiencies early on, machinery and equipment face reduced wear and tear, extending their lifespan and delaying costly replacements.

- Risk Mitigation: Undetected malfunctions can lead to expensive breakdowns. Thermographic inspections help avert these unforeseen costs by revealing potential risks in advance.

- Enhanced Productivity: With systems running optimally, there’s less downtime, ensuring that business operations proceed without costly interruptions.

| Financial Aspect | Benefit |

|---|---|

| Direct Savings | Reduced monthly energy bills |

| Operational Longevity | Extended machinery lifespan and reduced replacement costs |

| Risk Management | Avoidance of unexpected repair costs |

Driving Towards Sustainable Industrial Practices

In an era where sustainability is not just a buzzword but a business imperative, thermographic inspections play a pivotal role:

Carbon Footprint Reduction: By optimizing energy usage, industries can significantly lower their CO2 emissions, directly contributing to a more sustainable planet.

Resource Conservation: Less energy wastage means reduced strain on power grids and fewer natural resources utilized in energy production.

Reputation Management: A commitment to sustainable operations enhances a company’s image in the eyes of stakeholders, customers, and partners.

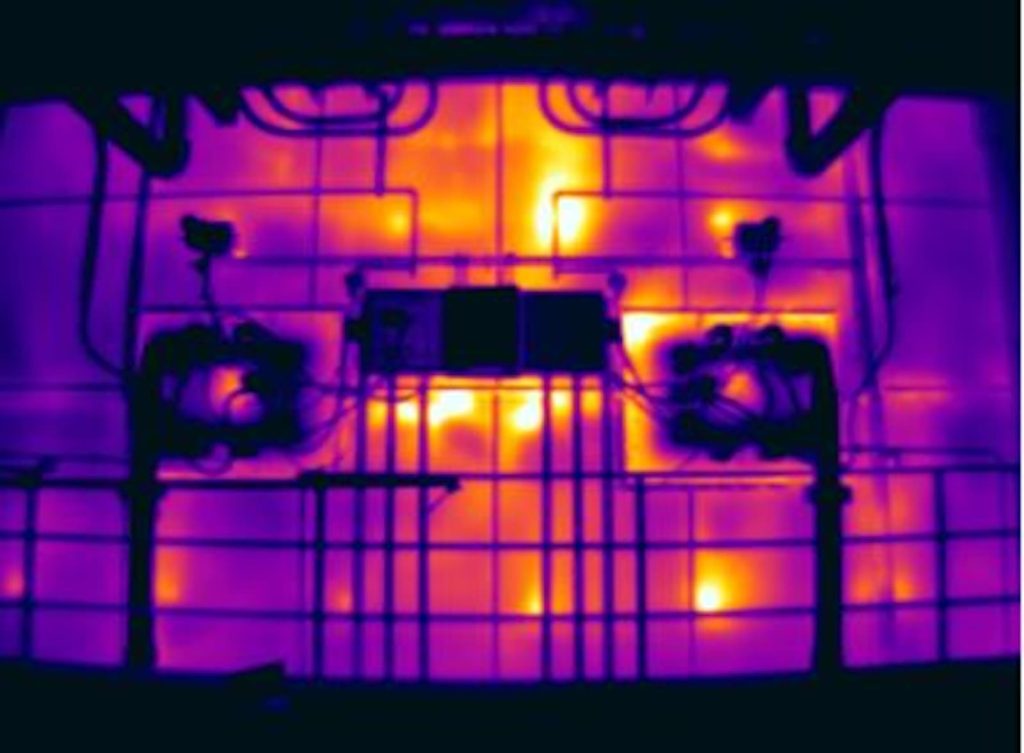

Proactive Maintenance with Infrared Insights

Maintenance based on guesswork is passé. Infrared insights offer a proactive approach:

Predictive Analysis: Thermographic data allows industries to forecast potential machinery malfunctions, ensuring timely interventions.

Safety Enhancements: By detecting overheating or faulty components, infrared insights prevent possible hazardous situations, safeguarding both assets and employees.

Optimized Maintenance Scheduling: With a clear understanding of machinery health, businesses can schedule maintenance activities more effectively, preventing unnecessary downtimes.

Meeting Compliance Through Accurate Measurements

- Documented Accuracy: Thermographic inspections provide comprehensive reports, rich in technical terms, supporting industries in showcasing their compliance with energy and safety standards.

- Risk Reduction: By ensuring systems and machinery are in top shape, businesses minimize the chances of violating safety and operational standards.

- Stakeholder Confidence: Transparent, documented adherence to standards fosters trust among investors, partners, and regulatory bodies.

Benefits of Opting for Thermographic Inspections

Selection of Cutting-Edge Thermographic Cameras

The cornerstone of accurate thermography is the use of advanced equipment. At TP Europe:

Technological Prowess: We prioritize cameras that offer high-resolution imaging coupled with a broad temperature detection range, ensuring no anomaly escapes our notice.

Real-time Processing: Our equipment integrates seamlessly with sophisticated software, allowing immediate data interpretation.

Durability in Varied Environments: Given the diverse industries we cater to, our cameras are rugged, ensuring consistent performance even in extreme conditions.

| Camera Feature | Benefit to Thermography |

|---|---|

| High Resolution | Accurate heat pattern detection |

| Fast Processing | Swift actionable insights |

| Rugged Build | Consistent performance across conditions |

Extensive Training of TP Europe’s Technicians

Equipment is only as good as its operators. Recognizing this, TP Europe invests heavily in:

Regular Workshops: These are organized to familiarize our technicians with the latest advancements in infrared technology.

On-field Training: Hands-on experience under expert guidance ensures that theoretical knowledge is effectively translated to practical expertise.

Certification Programs: We partner with reputed institutions to certify our technicians, emphasizing our commitment to excellence.

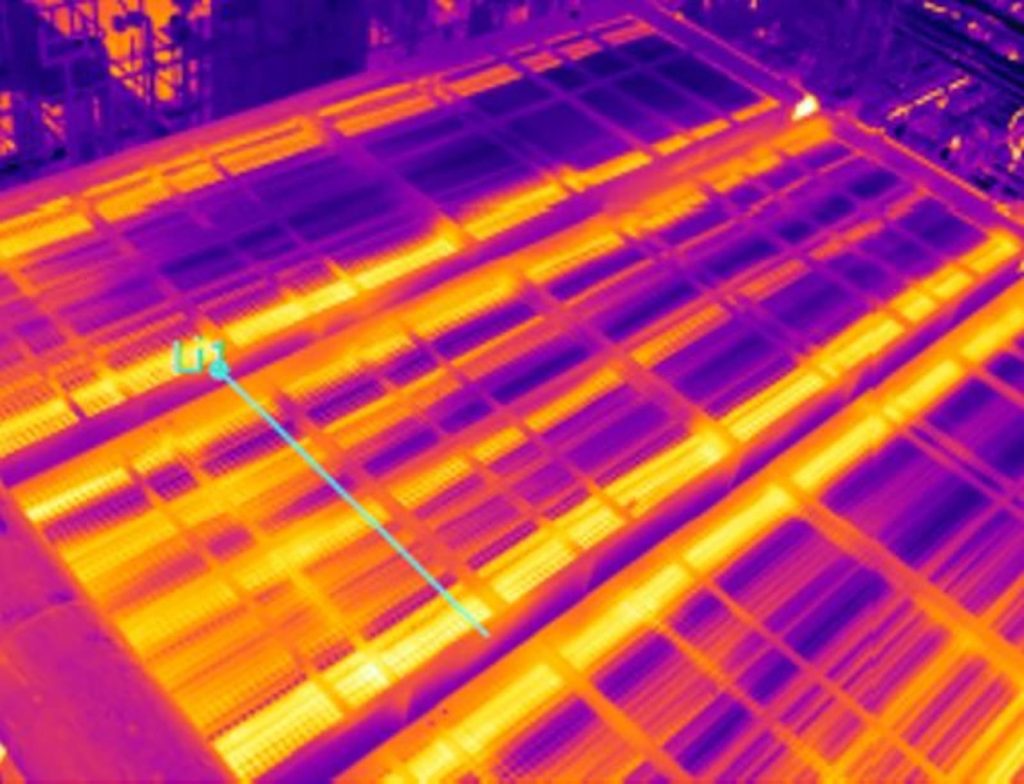

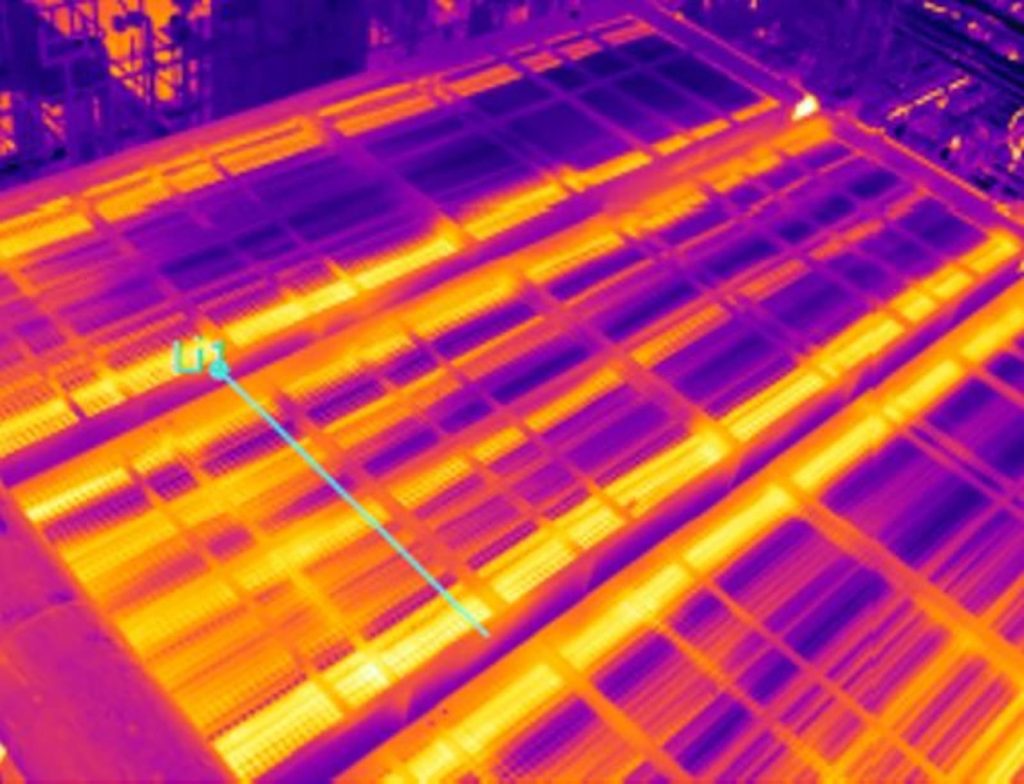

Conversion of Infrared to Actionable Thermograms

Capturing infrared radiation is just the beginning. Our strength lies in translating these readings into:

High-definition Thermograms: These visuals make temperature variations palpable, ensuring clarity in interpretation.

Technical Analysis: With a slew of technical terms, our reports offer an in-depth understanding of the thermographic findings.

Recommendation Lists: Post analysis, we provide a list of actionable steps industries can undertake to address identified inefficiencies.

Achieving Operational Excellence Through Thermography

TP Europe’s thermographic services do more than just detect energy inefficiencies. They serve as the foundation for operational superiority, streamlining processes, and ensuring consistent performance.

Conversion of Infrared to Actionable Thermograms

Routine checks form the backbone of industrial maintenance. By integrating thermography:

Consistent Monitoring: Regular thermographic inspections ensure continuous oversight of machinery health.

Early Anomaly Detection: Any deviation from the norm is immediately identified, leading to swift interventions.

Optimized Resource Allocation: With clear insights into machinery conditions, resources can be deployed more effectively, preventing over-expenditures.

Collaborative Analysis for Energy Efficiency

Our approach is collaborative. TP Europe believes in:

Joint Review Sessions: Engaging with client teams to discuss thermographic findings, ensuring a holistic understanding.

Customized Energy Solutions: Every industry is unique. We provide tailored recommendations to maximize energy efficiency based on specific needs.

Feedback Loops: Regular interactions post-implementation to gauge the effectiveness of the suggested measures and refine strategies.

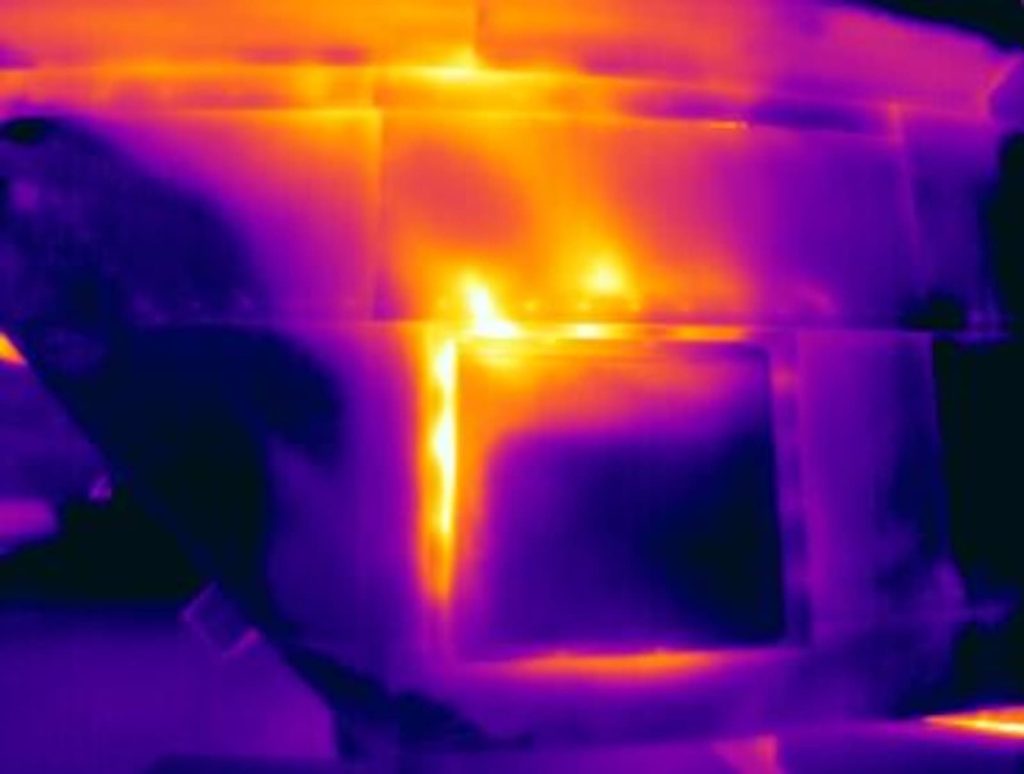

Enhancing Facility Safety and Employee Well-being

At the heart of TP Europe’s thermographic solutions is an unwavering commitment to safety and well-being. With the right insights:

Fault Detection: Our precise thermograms can identify potential electrical overloads or malfunctioning machinery, mitigating risks of accidents or fire hazards.

Safe Work Environment: Regular thermographic inspections ensure all systems are working optimally, leading to fewer on-site incidents and creating a safer workplace.

Employee Confidence: Knowing that their workspace adheres to top safety standards boosts employee morale and productivity.

Continuous Advancements in Thermographic Solutions

In the ever-evolving landscape of industrial needs and technological advancements, TP Europe remains at the forefront, ensuring our thermographic solutions are state-of-the-art and effective.

Adapting to Emerging Industrial Needs

Industries evolve, and so do their requirements:

Broadening Scope: As industries diversify, we expand our thermographic services to cater to newer sectors and varied machinery types.

Advanced Data Interpretation: Utilizing AI and machine learning, our thermographic readings are now interpreted faster and with increased accuracy.

Custom Solutions: Recognizing the unique challenges each industry faces, we tailor our solutions for maximum relevance and impact.

CCO TP Europe.

Joey, Chief Commercial Officer at TP Europe, thrives in sales, drawing satisfaction from client happiness and the company's growth. His dedication to staying connected to the field and ambition for global expansion are key to driving our mission forward.

Published: Tp Europe